-40%

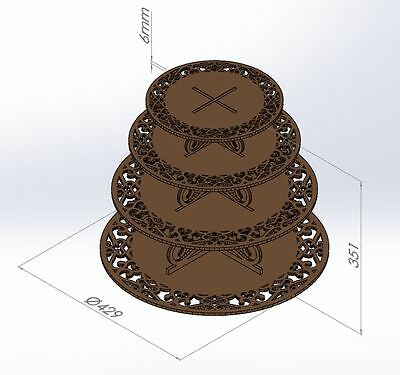

Camwood 5 x 10 CNC Router Complete Shown -See Revised Description about Shipping

$ 13728

- Description

- Size Guide

Description

Added 4/5/2020:For a short time I will pay 00.00 (at full purchase price) towards shipping and insurance via P.O.D. container within the continental US 48 with the understanding that it will cost me another 0+ to load and secure the unit at my facility. Contractual Terms and Conditions apply. Have your own transport and still want the discount? Contact me.

Also, I should mention that all the spindle cooling lines and coolant were recently been replaced. This is commonly done after several years because they commonly degrade over time and are prone to leak. New lines have been upgraded and made much easier to replace in the future.

This listing has been up for the past few months.

Please read all as it answers many questions and my apology for any redundancies. All direct contact info appears at the very end.

Hello, and thanks for looking at my lightly-used Camwood CNC in excellent condition. This is a workhorse of a machine which, unfortunately, I have had little time to utilize.

I recently revised this listing to take a more informative approach to advertise the history and details of the machine. To me it entails more than just the sale of a machine since I am offering my personalized support and training to whomever elects to purchase it and, therefore, establishing a relation ship with the buyer to ensure his or her satisfaction.

Since listing this machine, I did not anticipate to be pressed for time to demo it, as-planned, for those individuals who contacted me during that time due to a busy schedule that often took me out of town on business. Additionally, I must honestly admit that I was initially poised about selling it. I have reduced the original asking price less K with the OBO option. However, if you're looking for something cheap in a risky purchase just to get you by, this is probably NOT for you since I am offering it fairly priced, almost half the cost of what I have into it.

Ideally, I was hoping to sell it locally and establish a relationship with a prospective buyer to whom I could send my future files, but that was a little impractical and to buy another machine of this caliber would be too expensive in today's market. My apologies to anyone who I missed the opportunity to meet and demonstrate the capabilities of the machine. I am a little better-situated time-wise now to arrange demos into the near future for those interested.

Fortunately, I was able to find time to make a new vacuum plenum with spoil board as well as to modify the 5 zone PVC vacuum piping to make it a little more efficient than its previous, "reverse waffle" design that worked well during the short time I used the machine with vacuum.

There are literally hundreds of different vacuum configurations to consider and there is a science to it depending on your specific needs. I chose a couple of similar designs that suited mine and implemented them. The vacuum array can easily be modified further, if desired, and I have all the necessary files to accomplish that. Presently, it can accommodate 5' x 10' sheet goods with sufficient vacuum supplied via three-to-five Shop-Vacs. Currently, I use three vacs. Alternately, a vacuum pump can easily be added.

I'll try to provide as much information here as I'm able to answer any questions about it, just as I am willing to offer guidance and support to anyone who elects to purchase it. In a manner of speaking, this machine is like a pet to me and I have treated it accordingly. I would like to see it go to a good home, unless things change and I decide to keep it and pick up on CNC in the direction I was going.

I purchased this machine new at the turn of 2008-2009, specifying the components for its construction upgrading the nominal stock features as-spec'd.

It took nearly a year to get everything in place and setup with electrical lines,tooling, (dust collection system came later) before performing any CNC on the hobbyist level with intentions of expanding my applications to instrument-making, parts, and prototypes, etc., and, thus, why I purchased a large machine with the consideration of future expansion. Subsequently, an immediate family member became seriously ill in 2012 that interrupted my pursuits when I became their primary care advocate.

As a result, this machine has had very little use since I purchased it and I thought it might be a good idea to find it a new home where it can get the workout it or which it was designed. For all intent, it is in 'like-new'condition while CNC machine design has not changed much on the hardware end.

Although this may look like a typical Camwood (there are still a some newer ones around under this brand name) there are several differences: I personally spec'd and upgraded a lot of the hardware when I ordered it, adding the required software to do what I needed. Since purchasing it, the sales team that sold it to me moved on to start their own CNC company under another branded name selling high-end CNC's.

At that time I also considered and looked at several new and used machines used in industry. I found the used ones to be pretty beat-up, although a few looked nice and seemed to perform OK. I was advised by my CNC associates to go the path I did in buying a new, large machine, specifying high-end stepper motors and other integral components.

The water-cooled 3 HP HS spindle is more than sufficient for most industrial applications and, in this instance, bigger isn't always better especially when replacing parts somewhere down the line. For example, a new spindle, if ever needed, is readily available and affordable and every horse power above it seems to get incrementally more expensive. So, 3HP was the wise, mid-range choice, capable of industrial applications.

This is a heavy, vibration-

stable

industrial grade machine for which I carefully spec'd the components; e.g., stepper motors, racks, etc., but only used it for light-duty hobbyist-level work at home occasionally cutting urethane foam, acrylics, di-bond, soft woods, etc.

It does NOT come with a tool changer and takes only minutes to change tooling and re-zero the z axis. Tool changers alone can sometimes cost as much as a machine itself and adds to the learning curve of precision machining. A nice add-on to a machine, but wasn't necessary for most of my purposes.

This also comes with large wide-screen monitor not shown in pictures. Attachable side panels were left off since I've owned the machine allowing me access to the vacuum piping below and are still in their original packaging.

Probably best suited for local sale and pickup within a reasonable distance from the Southern New Jersey and Philadelphia Metro areas or, alternately, the tri-state area (NJ,PA, DE). Best method of moving the machine is a POD container.

Specifications and details appear below.

This machine comes with everything; namely, the CNC table with 3 HSP single phase water cooled spindle, control box, computer and monitor, Smooth-Stepper,table, chair, tooling (over K worth) including V-bits, large planning bit,end mills and round noses, a full array of various size collets, 3D modeling and tool path software, new Grizzly dust collection system, collection sliding hanger, and a custom, modular vacuum hold down system, training and support,instruction manuals, grease guns, etc., and I will assist in loading it onto to a truck and securing it for transport and setup at your location.

Again, this machine has had very little use in the time I have had it. More specifically, the machine has very few hours of light use estimated at 3 or 4 dozen times at most cutting mainly urethane foam products, some acrylics and soft woods only. It is also capable of cutting non-ferrous materials. It was close 12 months after purchasing it that I had everything in place to get it up and running. As it stands, it's ready to move, plug in and get going CNC'ing.

It runs a Mach3 CNC controller with a “Smooth Stepper” for multitasking while the machine is in operation.

I prefer to demo and sell this direct to someone, so kindly contact me for further details or questions you may have. It is an excellent and well-maintained machine with, as said, minimal hours of usage. All and everything works excellently.

A similar or equivalent machine with all that is offered with it would be priced well over K in 2018 as prices on everything have gone up. I have priced this to sell. If it does not sell to anyone aspiring to add CNC to its operations, I am happy to keep it and continue on the path of R&D of creating CNC products on a limited scale as time allows me.

One couldn’t ask for a more ideal arrangement. Try finding a better deal with what is all-inclusive.

Planning and training is vital to CNC and my expertise will allow the buyer to be up and running in little time.

Purchased at full-price and based on the buyer's location I will contribute a portion of those monies toward transport at the time of contract.

I accept cash, bank wire transfer or certified check only. NO PAYPAL, overseas,or long distance freight shipping. Sale is final subject to contractual terms and conditions.

WR510 Specifications:

•Material processing dimensions of 62" wide x 122" long x 8"gantry height.

• Fixed universal aluminum T-slot table for simple clamping of work piece to machine.

• Moving gantry bridge rides on high precision HIWIN linear rails for consistent movement and accurate cutting.

• Welded structural steel machine base provides a solid foundation for superior cut quality.

• he tool gantry and bridge travel by rack-and-pinion and the vertical axis travels on ball screws for smooth

•consistent movement

• Industrial-grade direct drive 3 HP router spindle is liquid cooled for cool & quiet running and extended life

•Variable tool speed up to 24,000 RPM allows for the right cutting speed in any application

• X- andY-axis 1,500 IPM Traverse speed for quick movement between cutting cycles to reduce total CNC machining time

• Windows based CNC control comes pre-loaded on a DELL PC with a 27"monitor(included); very intuitive interface, quick to learn and easy to use

•Compatible with virtually all CAD/CAM programming software on the market

• Unit pre-wired to run on a standard 60 Cycle, 208/220/240 Volt Single-Phase outlet;easy set up, can be done by the user

• Includes 2 dust hoods with 4" diameter inlet

THIS IS AN AD FOR PROSPECTIVE BUYERS TO ARRANGE FOR A DEMO. WITHIN A WEEK OF CONTRACTING,I WILL ASSIST IN THE PREP AND LOADING OF THE MACHINE ON TO YOUR TRUCK OR A CONTRACTOR'S WITH SETUP AND TRAINING AT YOUR LOCATION IF WITHIN REASONABLE DISTANCE.OTHERWISE, I WILL AM WILLING AND AVAILABLE FOR SUPPORT.

THIS MACHINE COMES WITH EVERYTHING YOU REQUIRE TO GET IMMEDIATELY STARTED WITH PRODUCTION, VECTOR AND 3D SOFTWARE, TOOLING, ETC.

PLEASE SEND A MESSAGE THROUGH EBAY TO ARRANGE TO SEE THE EQUIPMENT PRIOR TO CONTACTING BY PHONE WITH ANY QUESTIONS YOU MAY HAVE. All Sales final per terms and conditions. Cash, certified check only, No shipping, local pickup only in Southern NJ 08034 / (Tel: 18564187146). IF I AM UNAVAILABLE TO PICK UP, PLEASE LEAVE A MESSAGE AND I WILL GET BACK TO YOU. IT IS BEST TO FIRST CONTACT ME WITH AN EMAIL. THANKS