-40%

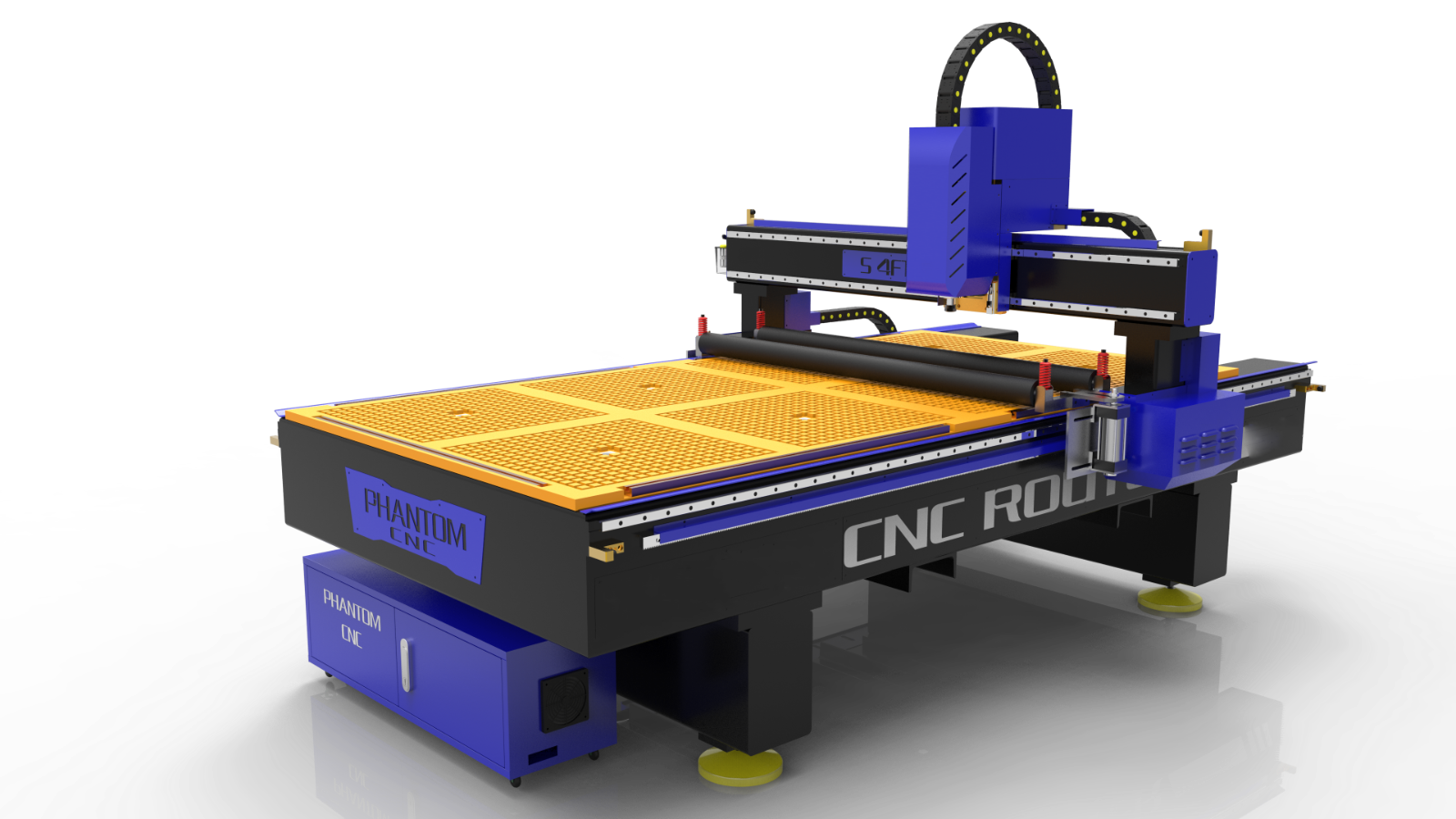

USA! 51" x 98" 4'*8' Ad and CNC Wood Router Machine with 3KW 6HP 4.5KW Spindle

$ 8447.47

- Description

- Size Guide

Description

Phantom CNC Systems S SeriesCNC Router Machine T-slot table with

6HP

spindle

The Machine is fully customizable. Options include Oscillating Tangential knife, Vision Registration system which uses a camera and software to eliminate errors while cutting, the Automatic Tool Changer for rapid tool changes while machining, a misting system for use while cutting aluminum and other non-ferrous metals, CAD/CAM software, control system and many more.

The offers virtually any width and length, 5*10

’

6.5*10

’

6.5*13

’

, and more. it's an endless list of options and is most popular in sign making, metal fabrication, plastic fabrication, and woodworking.

Machine Details

The configuration as follow:

(1) Working area:

8

*

4

*

.65

ft

(2) Spindle:

6HP

A

ir cooling spindle

(3) Inverter:

7HP

I

nverter

(4) Control system:

Handle c

ontroller system

(5) Driver system:

D

river

and R

educer structure

(6) Transmission: XYZ by linear guide+Flange slider+ XY by Precision 1.25

module helical rack, Z-axis TBI ball screw

(7) Rack design: Y-axis double-layer protection sheet metal design, rack dust-proof sheet metal design to

better product and extend the life of the drive system.

(8) Table: Vacuum table

(9) Vacuum pump: Vacuum table with

7HP

air cooling spindle

(10) Control cabinet:

S S

eries Independent portable optimized design separated control cabinet.

(11) Oil-mist cooling system for metal

(12) Electrical Parts: Famous electrical components Japan Omron limit photoelectric switch

(13) Filter, Cast steel motor Box

(14) Lubrication

S

ystems:

A

utomatica

l

l

ubrication

oiling system

(15) Automatic

P

roofreading: Tool Sensor

(16) Protection Switch: Machine fail-safe emergency stop switch

(17) Machine structure: the Heavy-duty thickened machine is welded together by

0.65

*

0.98 inch

square

tube, side hanging structure, heavy columns,

5.9* 7.5-inch

gantry

(18) Z-axis Spindle Mounting Plate: Z-axis drive head part,

0.82-inch

wide machine head adopt High

precision aviation aluminum alloy T6061/6063, which are all made by professional precision machining

centers.

(19) Machine assembly process upgrade, dial indicator calibration

(20) New Type Machine is of reasonable design, accurate measurement, high precision, good stability,

the excellent technical performance and wide application range

(21) Forklift loading and unloading reserved, which can better protect machine body and cargo's carrying

capacity.

(22) Machine body and machine legs can freely be separated, disassembly delivery can save shipping

costs.

(23) Toolbox(

A set of bits, extra aluminum bits, Hold Down Clamp, Spindle Spanner, Spanner, Spindle Nut, Control system, Collet, Key, Mach3 Disk, Mach3 Operate instruction, Spindle Belt, Foundation Bolt*6

Working Voltage: AC

110

V

220V

/

6

0HZ

6HP

Air cooling spindle

Because the accuracy of the CNC router machine greatly depends on the spindle. The High-quality

Phantom CNC Systems

series CNC Router machine comes with

6HP

air cooled high-frequency spindle. This precision spindle requires no maintenance, uses industry-standard ER32 collects. Fully programmable speeds from 6000 to 24000RPM, and comes complete with pneumatically retractable vacuum hood.

7HP

Inverter(VFD).

The whole electrical system is consisting of a CNC machine, variable frequency drive, time relay, and brake assembly.

We adopt

6HP

Spindle &

7HP

VFD, Greatly improve the machining accuracy and production efficiency of the CNC machine, play an important role in product quality improvement, production increase, cost decrease, automation level increase, and maintenance reduced.

Z-axis Transmission Way.

TBI High-Precision Ball-screw Transmission

1) Higher efficiency than traditional ball screws.

2) Gothic groove shape, the shaft direction clearance can be adjusted to a minimum and can be easily transferred.

3) The internal circulation method is applicable to many different scenes, and the circulation method is selected according to its own needs.

4) Use rigorous materials, high heat treatment, and processing technology to supply durable products.

X, Y-axis Transmission Way.

X Y by

Precision 1.25 module helical rack gear.

Z by

High-Precision Ball-screw Transmission

XYZ With High precision

Linear guide+High assembly Flange slider

Precision 1.25 module helical rack gear.

Helical teeth gears provide continuous engagement along the tooth length and are often quieter and more efficient than straight tooth gears and also offer higher loading for the same rack width. Helical tooth gears resemble spur gears in the plane of rotation but include teeth that are twisted along a helical path in the axial direction.

Transmission guide.

Linear guide+High assembly Flange slider

(1)High positioning accuracy, high repeatability

(2) Low frictional resistance, high precision maintained for the long period

(3) High rigidity with four-way load design

(4) Suitable for high-speed operation

(5) Easy installation with interchangeability

M

otor

Drive System

.

The

4 m

otors are installed on all axes to ensure precise positioning of the gantry and the spindle in accordance with a predetermined program at high speed.

T

hey

are a well-proven high degree of reliability.

The machine is installed 4 sets of motors and Driver. Y-axis

use double motors drivers way.

Reducer Structure.

D

esign 1:4 gear reducer install on the driving motor makes the motor is more powerful, and having a long time service life.

Driver

Systems

.

Selecting a chopper driver and configuring it for a specific motor requires a good understanding of both the motor and the controller. Mismatched motors and drivers can result in a disappointing performance. Or worse: damage to the motor and/or controller. we deal with the most important part: making sure that your motor and driver are compatible

Vacuum

table with T-slot table

Or we can offer a professional vacuum table, Details please contact us.

Or You can choose

T-Slot Clamping Table

. it

is the most simple table structure that fixes a working object through a clamping kit. Without the requirement of

220

V 3-phase electricity to power a vacuum pump, it's the only table solution for our Sign-Making Routers that target home-based businesses and hobbyists.

Air cooling vacuum pump

The vacuum table needs a Vacuum pump. If you want to choose a vacuum table. please add it. The strength of the vacuum determines how much of the air pressure is actually going to work to hold down your workpieces. Less vacuum means less pressure.

Famous electrical components.

CNC electronics are a vital part of any CNC machine. Aside from the Motors and CNC controllers, There are many electronic components that assist in the machine operation.

Many people feel more threatened by electrical components than the mechanics of a machine. we create a fully working machine.

P

endent

control system.

Pendent turns a typical computer into a CNC machine controller. It is very rich in features and provides great value to those needing a CNC control package. It doesn't need PCs to control the motion of motors (stepper & servo) by processing G-Code. While comprising many advanced features, it is the most intuitive CNC control software available. it is customizable and has been used for many applications with numerous types of hardware.

Automatic oil lubrication system.

Protecting machinery is an ongoing responsibility. To guarantee high performance over the course of time requires both long-term and spontaneous maintenance. A manual lubricator not only distributes grease or lubrication for a variety of large machinery, but it also allows operators to do so in a timely manner.

Dust Collector With Double Bags.

Dust Collectors keep the air in your shop clean and keep you safe while you're hard at work. Exclusive technologies dust collection units with the ability to capture particles.

Tool sensor.

This device takes the guesswork out of tool changes and ensures that every tool path that you run is accurate. Consistent Z height across tool changes is critical, especially when running multi-tool jobs like cabinetwork, raised panel doors, and intricate 3D carving projects.

CNC Tool Sensor allows for easy and accurate "Z" zero position for single and multiple tool changes through the program.

1. Cabinets & Furniture

Custom and general cabinet manufacturing are some of the most popular applications for CNC routers. Phantom CNC Systems CNC routers have brought industry standards to a new level with our quality and components, delivering what you would find in much higher-priced CNC routers for a cost-competitive with less industrial designs.

Our routers give cabinet makers the ability to manufacture many different styles of cabinet sets, closet sets, doors, drawers, shelves, and countertops with ease and precision. These machines also allow shops to expand their capabilities to include intricate furniture designs such as chairs, tables, rail systems, and much more. With 2D, 3D, and even 4th axis capabilities, our machines let you drill quicker, cut more accurately, and get a completely smooth finish without ever having to hand sand. Phantom CNC Systems CNC machines are only limited by the imagination. Cut costs and increase profitability in your cabinet and furniture production with a NEW Phantom CNC Systems CNC router.

2. Sign making & Carving

Phantom CNC Systems CNC routers are found in the everyday hobby shop all the way to full-production manufacturers in the sign and carving industries. Whether you are working with foam, wood, plastic, acrylic, aluminum, brass, or a variety of other materials, we have a Phantom CNC Systems CNC router that fits your sign-making and carving needs. With a wide range of options including vision recognition systems, ADA signage capabilities, tangential knife systems, or multiple tool capabilities, there is an option for any level sign shop.

Our CNC routers bring the ability to design a very simple 2D project or a much more complex 3D sign or carving. With the Phantom CNC Systems CNC router, you can use existing. DXF files, clip art, and photographs, or you can create your own design from scratch with our simple but powerful controls. Whether you are looking for a “rustic” look or a full-production finish, Phantom CNC Systems has the capabilities to deliver the result you want. Our systems have raised the bar on the average CNC router by giving shops and manufacturers the ability to produce better signs and carvings for less.

3. Musical Instruments

Creating a musical instrument takes flawless precision and accuracy. Phantom CNC Systems CNC routers are built with high-quality components to deliver the reliability and value that musical instrument manufacturers can’t find elsewhere.

Phantom CNC Systems has brought the ability of mass production and custom one-off fabrication to many musical instrument manufacturers, allowing them to tailor their products to the customer. Don’t limit yourself to generic instruments because of average equipment. Become a maestro at musical instrument manufacturing with the unparalleled technology of a Phantom CNC Systems CNC Router.

4. Plastics & Foam Metal Fabrication

To get precision and accuracy when cutting plastic or foam, you need a machine that doesn’t compromise on quality. Phantom CNC Systems CNC routers help many manufacturing facilities produce better plastic and foam products. Our routers are equipped with an upgraded frame, gantry, and drive system technology to handle a wide range of plastics and foams so you get flawless results every time.

Whether you are working with sheets in a high production setting or one-off parts in a more labor-intensive product, a Phantom CNC Systems CNC router has the solution to help increase production while maintaining a favorable budget. Don’t outsource your materials when a Phantom CNC Systems CNC Router can bring your work in-house and put the dollars back in your pocket!

5. Prototyping & 3D Modeling

Prototyping and 3D modeling are often essential parts of the production process. You need your prototypes and 3D models to come out perfectly so you can see the true possibilities of your concept. Phantom CNC Systems CNC routers have all the capabilities you need to create prototypes and 3D models that will become the next breakthrough product.

Phantom CNC Systems CNC routers are found in some of the most prestigious prototyping and 3D modeling facilities in the world. Some of the everyday products we use today were developed and prototyped on Phantom CNC Systems machines. Our systems allow you to scan, copy, engineer, and reverse engineer components so you can create the most innovative products. The added precision, dependability, and low operating costs of a Phantom CNC Systems router allow you to prototype and 3D model even the most advanced products.

6. Metal Fabrication & Steel Applications

When you’re working with metal, you need a cutting solution that will deliver power, precision, and a perfect finish. Our CNC plasma systems provide all the capabilities you need for any metal project including pipe, tube, corrugated metals, expanded metal, or flat sheet stock.

Whether you are a custom street or hot rod shop, race shop, or industrial equipment manufacturer, we have a CNC plasma system to fit your application and budget. Our machines are equipped with the necessary components and software to give you the ability to create some of the most extreme signs and yard art, HVAC, brackets, and other various metal fabricated products. Our unique software will help you finish this work.

Note:

If you don't know what kind of machine you should choose, please tell me the following questions:

1) What are the processing materials?

2) What are the max length, width, and thickness of the materials?

3) Do you want to engrave or cut? If for cutting, what is the max cutting thickness you need?

Then I will recommend the most suitable machine for you!

More Choices: Please call us:

The price just machine price. don't include any extra fees. you can also pick up the machine from our shop.

Vacuum Table CNC Router Machine

Equipped with professional metal spindle and aluminum cutter, for human design, can add guard railing for protecting kids and pets from being injured when they paly during machine working.

ATC 4th Rotary device

Rotary could be added on the side of the machine table or put it on the machine table, depends on your using habit.

You can choose the proper rotary's diameter and length according to your materials. It's mainly be used for processing some round or square materials.

ATC CNC Router

The machine could add linear or carousel tool changer, 4, 8, 12 tool holders could choose.