-40%

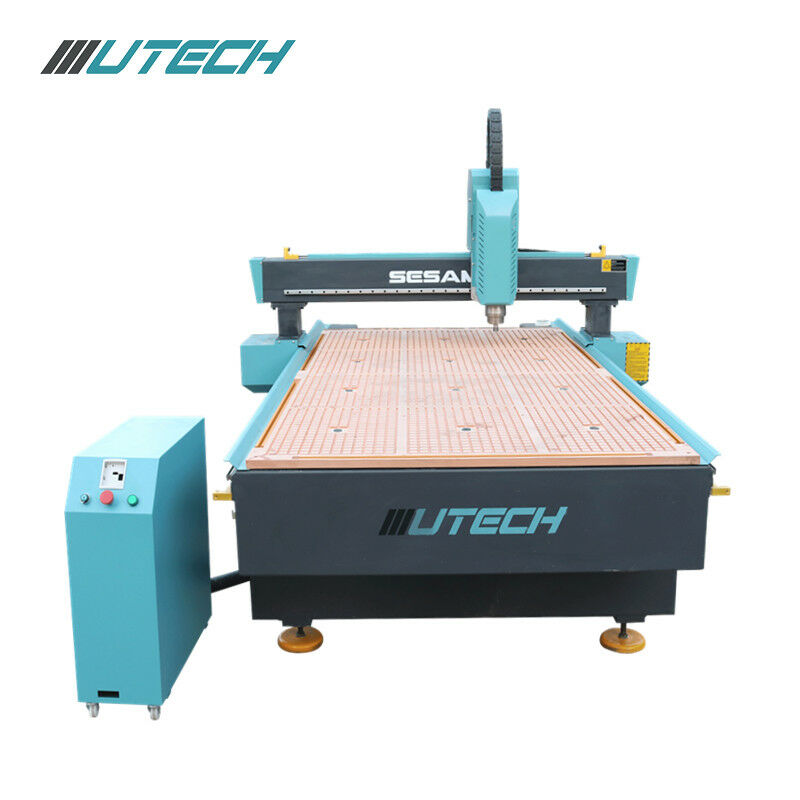

USB 3kw USB CNC Router Milling Wood Engraving Machine, Vaccum Table+Vacuum Pump

$ 2850.67

- Description

- Size Guide

Description

USB 3kw USB CNC Router Milling Wood Engraving Machine, Vaccum Table+Vacuum PumpThe

Sesame CNC

is a

Cost-effective

and

style novel CNC Router

that opens multiple avenues for your business. The sesame is constructed with a machine bed adapt 200*300mm thick wall steel square tube welded together and industrial quality precision bearings with high precision PMI rails on each axis. and Sesame cnc router machine that comes equipped with stepper motors and drivers reducer independent Portable detached optimal design control box and T-slot table.

And

Sesame is fully customizable

. Options include Oscillating Tangential knife, Vision Registration system which uses a camera and software to eliminate errors while cutting, the Automatic Tool Changer for rapid tool changes while machining, a misting system for use while cutting aluminum and other non-ferrous metals, CAD/CAM software, control system, and many machines.

Please note: Related machines

Product Description

SPECIFICATIONS FOR CNC ROUTER MACHINE

Model

Sesame-1325

Working area

X axis travel

1300mm

Y axis travel

2500mm

Z axis travel

150mm

Transmission device

X-axis transmission mode

precision helical tooth gear, PMI linear guide

Y-axis transmission mode

precision helical tooth gear, PMI linear guide

Z-axis transmission mode

precision TBI ball screw, PMI linear guide

Table structure

Vacuum table with T-slot

Travel speed

0-30000mm/min

Max. Power Consumption

(Without Spindle) 3.0Kw

Spindle power

3.2KW Water/3.5KW Air cooled spindle motor

Spindle speed

0-24000rpm/min

Diameter of cutter

φ3.175-φ12.7mm

Drive Motors

Stepper System

Command code

hPGL G-code

Working voltage

AC220V/50/60Hz, 3PH (Option: 110V, 380V)

Device interface

Standard PCI/USB interface Optional

Control system

Nc-studio/DSP controller/Mach3 controller

Resolution

0.01mm

Machine size

1980*2950*1500mm

Machine weight

1200kg

Running Environment Temperature

0 - 45 Centigrade

Relative Humidity

30% - 75%

Machine Details

Machine configurations:

#.Model: Sesame-1325 3 axis cnc wood router machine

#.Working Area: 1300*2500*200mm

#.Spindle Power: 3.2KW water cooling spindle(you can also choose 3.5kw air cooling spindle)

#.Spindle cooling way: Water pump

#.Inverter: 3KW Xinfutai Inverter

#.Table: Vacuum table with T-slot table

#.X, Y, Z axis Transmission Way: X Y axis 1.25 helical tooth rack transmission, Z axis Taiwan TBI Ball Screw transmission

#.Guide Rail: Taiwan PMI G20 linear rails+Flange Slider

#.Drive Motors: JMC 860H driver+Patent type stepper reducer*3+450B stepper motor

#.Operating System: Mach3 control system

#.Command Language: G Code

#.Software Compatibility: Option: Type3, Ucancam, Solidworks, etc.

#.Heavy duty body (After Quenching process, no deformation, 8-10 bed, very stable )

#.Cast gearbox (stronger stability, high precision, and long life ) woodworking machine

#.Famous electrical components

#.Japan Omron Limit switch electric ( Low tension )

#.Tool sensor, Filter

#.Toolbox

#.Working Voltage: AC380V/3PH/50Hz(option:220V/50hz,single phase)

Optional parts:

1. 4.0, 5.5KW water cooling or air cooling spindle

2. Water-Cooling Table-Water tank

3. Control system: Rich auto-A11 DSP control system(option:NC-studio)

4. Inverter: Delta, Fuling Inverter.

5. Motor and driver: servo motor and driver.

6. Dust collector.

7. The vacuum pump(optional water cooling or air cooling).

8. T-slot table

3.2KW Utech Water cooling spindle

Because the accuracy of cnc router machine greatly depends on the spindle. The High-quality SESAME series CNC Router machine comes with 3.2kw water or 3.5 air cooled high-frequency spindle. This precision spindle requires no maintenance, uses industry standard ER collects. Fully programmable speeds from 6000 to 24000RPM, and comes complete with pneumatically retractable vacuum hood.

3.7kw Xinfutai/Fuling Inverter(VFD).

The whole electrical system is consisting of a CNC machine, variable frequency drive, time relay, and brake assembly.

We adapt 3.7kw VFD, Greatly improve the machining accuracy and production efficiency of CNC machine, play an important role in product quality improvement, production increase, cost decrease, automation level increase, and maintenance reduced.

Vacuum table with T-slot.

Vacuum tables are devices that use suction to securely hold workpieces during machining. They are most commonly used during CNC cutting, whether with a mill or router or with a drag knife. They can be various sizes, and they are comprised of a perforated table top connected to the vacuum chamber, and a vacuum pump that continuously applies suction.

Z-axis Transmission Way.

TBI High-Precision Ball-screw Transmission (Taiwan)

1) Higher efficiency than traditional ball screws.

2) Gothic groove shape, the shaft direction clearance can be adjusted to a minimum and can be easily transferred.

3) The internal circulation method is applicable to many different scenes, and the circulation method is selected according to its own needs.

4) Use rigorous materials, high heat treatment and processing technology to supply durable products.

X, Y axis Transmission Way.

Precision 1.25 module helical rack gear.

Helical teeth gears provide continuous engagement along the tooth length and are often quieter and more efficient than straight tooth gears and also offer higher loading for same rack width. Helical tooth gears resemble spur gears in the plane of rotation but include teeth that are twisted along a helical path in the axial direction.

Transmission guide.

PMI Linear guide+High assembly Flange slider

(1)High positioning accuracy, high repeatability

(2) Low frictional resistance, high precision maintained for the long period

(3) High rigidity with four-way load design

(4) Suitable for high-speed operation

(5) Easy installation with interchangeability

Stepper motor.

The stepper motors are installed on all axes to ensure precise positioning of the gantry and the spindle in accordance with a predetermined program at high speed. Stepper motors are well proven high degree of reliability.

The machine is installed 4 sets of motors and Driver. Y-axis

use double motors drivers way.

Utech Patent 1:4 Reducer Structure.

Patent design 1:4 gear reducer install on the driving motor, makes the motor is more powerful, and having a long time service life.

Stepper Driver.

Selecting a chopper driver and configuring it for a specific motor requires a good understanding of both the motor and the controller. Mismatched motors and drivers can result in disappointing performance. Or worse: damage to the motor and/or controller. we deal with the most important part: making sure that your motor and driver are compatible

Famous electrical components.

CNC electronics are a vital part of any CNC machine. Aside from the Motors and CNC controllers, There are many electronic components that assist in the machine operation.

Many people feel more threatened by electrical components than the mechanics of a machine. we create a fully working machine.

Mach3 control system.

Mach3 turns a typical computer into a CNC machine controller. It is very rich in features and provides a great value to those needing a CNC control package. Mach3 works on most Windows PC's to control the motion of motors (stepper & servo) by processing G-Code. While comprising many advanced features, it is the most intuitive CNC control software available. Mach3 is customizable and has been used for many applications with numerous types of hardware.

Tool sensor.

This device takes the guesswork out of tool changes and ensures that every tool path that you run is accurate. Consistent Z height across tool changes is critical, especially when running multi-tool jobs like cabinet work, raised panel doors and intricate 3D carving projects.

CNC Tool Sensor allows for easy and accurate "Z" zero position for single and multiple tool changes through the program.

Manual oil lubrication system.

Protecting machinery is an ongoing responsibility. To guarantee high performance over the course of time requires both long-term and spontaneous maintenance. A manual lubricator not only distributes grease or lubrication for a variety of large machinery, but it also allows operators to do so in a timely manner.

Double Insurance Emergency Stop Button.

There is double insurance emergency stop switch. In case of an emergency, the worker can press any emergency stop button and the machine will stop working.

Machine Advantage

According to overseas custom demand and market research, as for the overall design structure of the bed body, we adopt separated type lathe bed structure. With the purpose of After ensuring

that the customer receives the equipment, there's no need to make a complete

disassembly and will not affect the operation of the equipment. In this

circumstance, we optimized the design structure, then, the final packaging size

of the product was saved by 5 cubic meters. Thus saving transportation costs.

The machine main body and the machine legs are freely separable when delivery the legs are disassembled and put on the table, which will reduce the machine's package size, then will save the shipping cost.

The bed is the backbone of a cnc router machine, our machine bed adapts 200*300mm thick wall steel square tube welded together, solid and not deformed

. After high-temperature tempering treatment to ensure the best strength and rigidity side arranged structure, heavy column,150*150mm gantry.

precision machined and stress relieved so that the foundation remains true and steady over the operational life of the machine. Compared to ordinary machines, it has better stability.

The forklift location display of Sesame CNC router machine.

Bed welding process increases the reserved forklift space, highlights two major advantages: First, it can better protect machine body and cargo carrying weight; Second, it's more convenient for customers to load or unload the equipment.

The Spindle Mounting Plate of Sesame adapts High Precision aviation aluminum alloy parts T6061/6030, Which are all made by professional CNC machining center. After the oxidation surface and low-temperature annealing treatment, the machine head is lighter and more durable. And the high requirement assembly process ensures the precision of the product again.

Sesame adapts Portable detached optional design control cabinet.

1)Interfacing reaches the purpose of plug and play.

2)Save more space.

Optional parts.

More power spindle.

4kw, 5.5kw Utech high-quality metal spindle.

All our CNC Routering systems are able to cut very thick plates by multiple passes. To achieve a fast turnaround time, deeper cutting depth is always be demanded. With most tooling, it is recommended to use cutting depth as tool diameter for optimized feed rate. For deeper cuts, you can always choose a lower feed rate but you can also use a more powerful spindle to maintain the cutting speed ( as long as tool bit won't break). Choosing a more powerful spindle is always recommended, which gives you the ability to cut faster and cut deeper simultaneously.

Hybrid Servo Motor and Driver.

Sophisticated control techniques have produced the hybrid servo motor system from the motor style commonly called a hybrid stepper motor when powered by an open-loop step driver. The result is a high-torque capability with a speed-torque range well matched to direct driving belts and lead screws, as well as other loads.

The hybrid servo motor is a good optional.

Rotary on the table.

4-Axis rotary table assembly comes complete with a 3-jaw chuck, tailstock, and guide track for easy tailstock movement and center alignment. The addition of 4-axis rotary table assembly adds greater functionality to the machine's capabilities allowing for 4-axis cutting in both 2D and 3D carving and indexing functions.

(Utech rotary size has 0-80mm, 0-100mm, 0-150mm, 0-200mm, diameter rotary axis for your choice).

Rotary by side.

Profession side rotary structure.

Do you usually use the rotary?

Does your work need a big rotary?

The Profession of rotary structure can solve these questions.

(Utech rotary size has 0-200mm, 0-300mm, 0-400mm, 0-500mm, diameter rotary axis for your choice).

Dust Collector With Double Bags.

Dust Collectors keep the air in your shop clean and keep you safe while you're hard at work. Exclusive technologies dust collection units with the ability to capture particles.

Air cooling vacuum pump-5.5kw.

Vacuum table needs a Vacuum pump.

The strength of the vacuum determines how much of the air pressure is actually going to work to hold down your workpieces. Less vacuum means less pressure.

DSP Control System.

1.Totally independent from PC platform;

2. Directly read files from U Disk;

3. Easily process G code or PLT file with supersize;

4.Strong system and process file examining function;

5.Easy to update system program;

6. It supports high micro step which makes the precise and fast process possible;

7.Support to process part of the file;

8.Reliable data protection and recover function;

9.Friendly operating interface

Water cooling table.

Water cooling table applies to Stone, Soft Metal such as aluminum copper, etc.

cooling on the tooling bit and working object is constantly required to avoid overheating and result in damage to the tool bits and the working piece.

we provide a set of Complete equipment for this water cooling table.

Packing & Delivery

Package Details:

1. Our Wooden Case is after fumigation treatment. Needn`t timber inspection, saving shipping time.

2. All the spare parts of the machine were covered by some soft materials, mainly using Pearl Wool. Avoiding all damages that could happen in the delivery process. Then we`ll cover plastic wrap out it tightly, make sure intact of the covered soft materials, also avoiding Waterproof and rust proof.

3. The outmost is Wooden Case With Fixed Formwork.

4. The bottom of the wooden case has a firm iron jack, convenient for Handling and transport.

Our Company

Shandong U-MAY CNC Technology CO., LTD. Specializes in the research, development, production of CNC MACHINE. Our brand "WIN" has a considerable reputation in domestic similar products, which has been widely used in wooden furniture, advertising, craft gifts, packaging and printing, logo and etc. Our products have been exported to many countries and regions such as Europe, Russia, Asia, Africa. We are committed to the enterprise management philosophy "Integrity-based, constant innovation, effective communication, quality services" and the goal of "Technical service customer", but also great attention to product design, manufacture, installation, adjustment. We will still try our best to maintain one-stop professional service.

Our Service

Machine Testing

: To ensure the quality and stability of the machine, we use the most advanced production and testing equipment

, to check the quality and performance of our

industrial cnc equipment in each production step to ensure our equipment quality and

stable performance.

Quality

: In order to guarantee the performance and quality of our products, we strictly control all processes, x, assembly, our equipment quality, and delivery.

Export

: our products are not only sold in China in large quantity but also have been exported to more than 150 countries and regions in the world, including Germany,

America, Italy, Russia, South Korea, Turkey, Brazil, South Africa, India, the United The Arab Emirates, and so on.

Service

: sell the best machines at the best prices, and provides industry-leading customer service. Our technical engineers provide comprehensive pre-sale and after-sale support and service all the time.

Please notice, Because the machine is big and heavy, the price just includes delivery to your port by sea. For New York port etc. We can offer free shipping.

In general, it will take around 30-45 days for shipping. The price doesn't include customer Customs clearance,

customs duties, and buyer local extra fees. We can also deliver to your address, Please contact me for further details.

Related Machines

Sesame-Double head cnc router+Air squeezer service

Sesame-High performance cnc router machine

Sesame-Multifunction visual positioning cutting machine

.

Sesame-Processional Vacuum table cnc router machine.